Positech Innovation wheelchair cushion manufacturing steps

Positech Innovation Inc is proud to say that all our products are designed and manufactured in Quebec!

The entire manufacturing process takes places in our Terrebonne offices.

Through this blog, we will go into more detail about the various stages involved in designing a wheelchair cushion.

Design stages

1. Cushion design and creation

The first step is to create the cushion. We will make various sketches to create a cushion that will meet the different needs of the users. We have a complete range of wheelchair cushions, and we are constantly improving it.

2. Choice of materials

Then we must go through the raw material selection process to choose material that reflect the quality of our products. We choose fabrics that are durable, comfortable, and easy to clean, so we can design a cover of superior quality. Then we go on to foam selection (high density, low density, viscose, etc.) to offer users optimum confort and support.

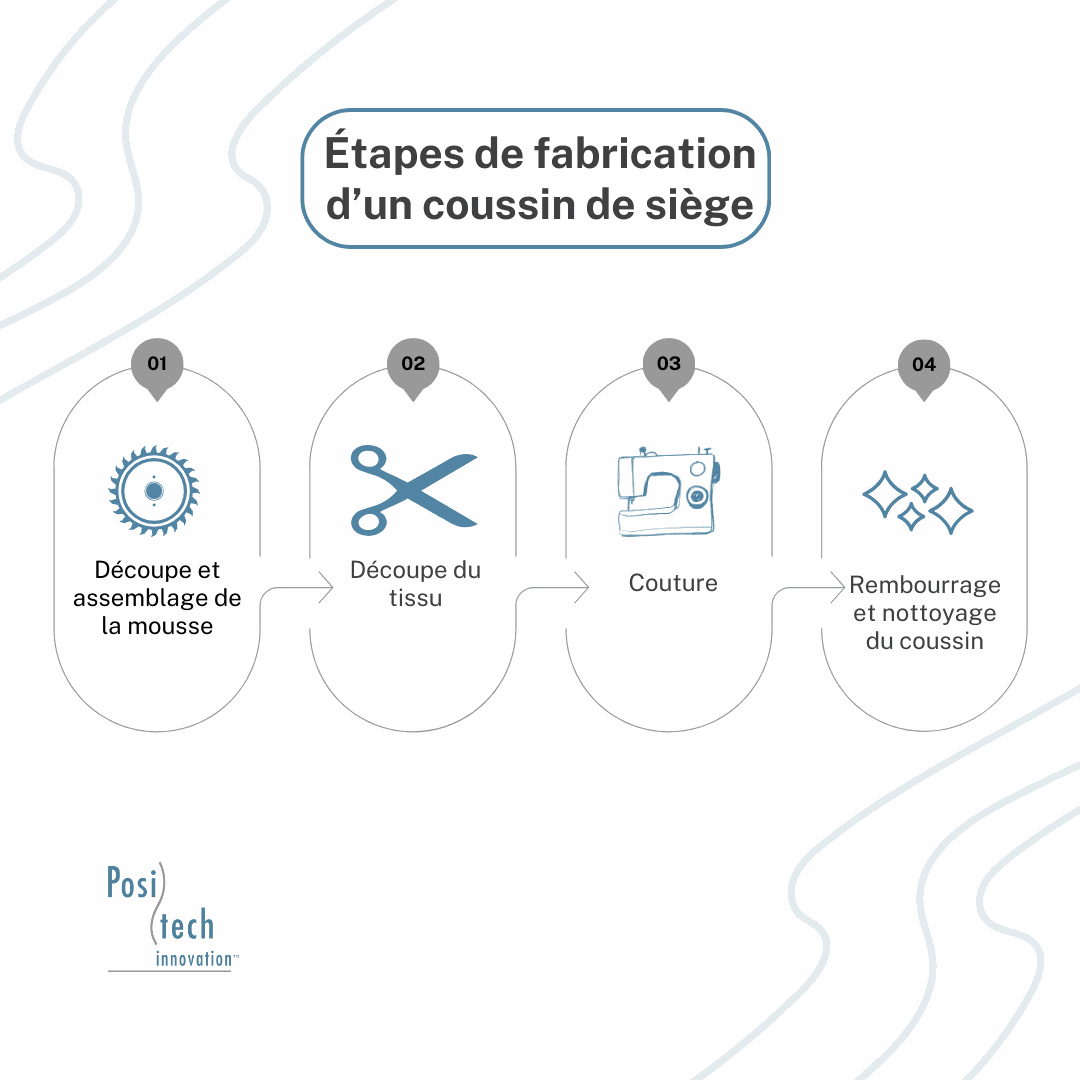

Manufacturing steps

1. Foam cutting and assembly

Once we have received your order, we will cut the foam required according to the model and size of cushion ordered. Once the foam has been cut, we will assemble the various foams with glue to form the cushion.

2. Cutting fabric

Once the order has been received, the patternmaker cuts the fabric required for the cushion ordered. The measurements will differ according to the model ordered and the size.

3. Sewing

The seamstress assembles the cover by sewing the various fabric parts, zippers and Velcro fasteners, following the instructions for the specific cushion model.

4. Padding and cushion cleaning

We insert the foam into the cover through the zipped opening provided. Then we will adjust the foam so that it sits snugly in the cover. Once assembled, we will clean the cushion so it's ready for delivery.

Don't hesitate to contact us if you have any questions, we will be happy to answer them!